Robotic Fabrication Student Project: Micro-Wave

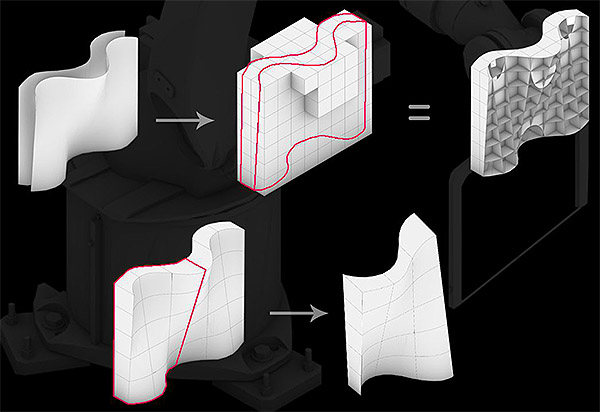

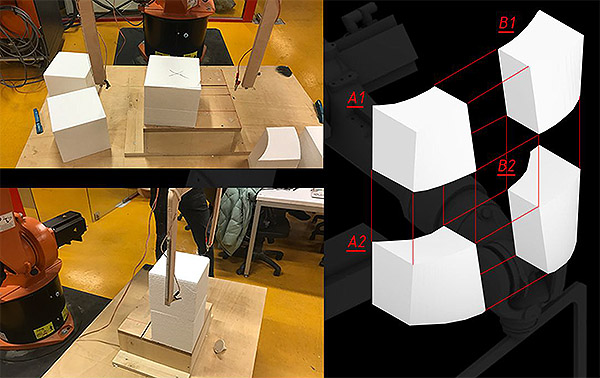

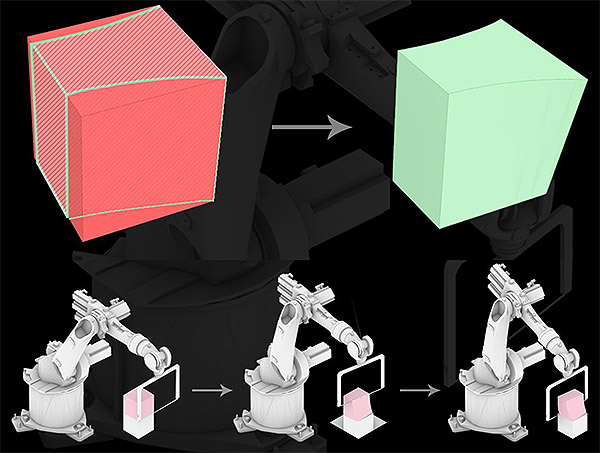

This is a robotic fabrication student project developed in the Digital Fabrication elective course in 2018. This group of students experimented with the hot wire cutting of EPS foam. Their aim was to create curved surfaces by using a straight wire. Design research started with a literature study of precedents. Then, after several cutting experiments with the available hotwire cutter tool, they gained better control over the technology. However, they found the available tool too large and inefficient. They decided to re-design and produce their own tool, with suitable dimensions for their purposes.

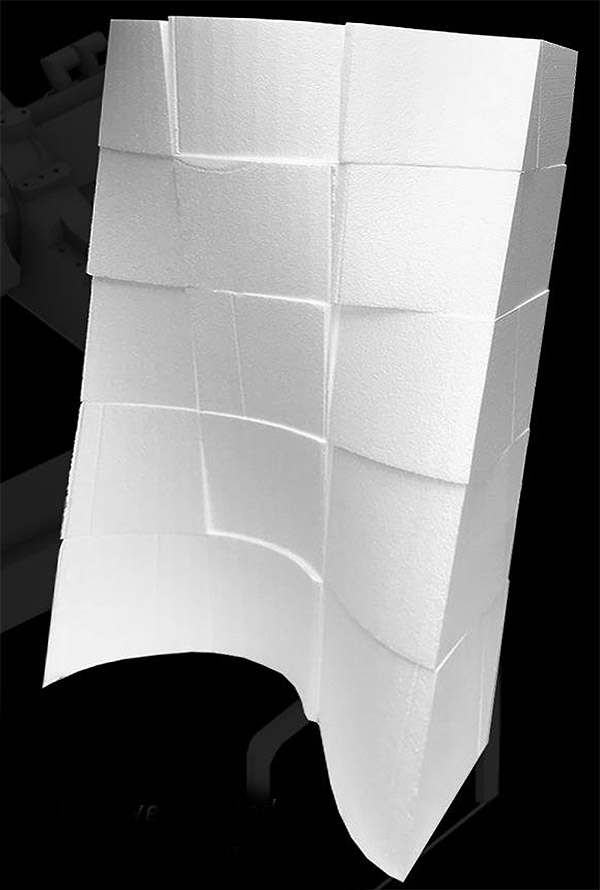

The production process started with the determination of the correct module size. It was 20kg/m3 EPS foam in 17cm cubes. On the other hand, they created the digital model of a curved wall-like shape and subdivided it into blocks. It took a total of 3 classes (9 hours) to design and produce the tool and the wall shape. The students finally prepared separate robot programs to cut 15 blocks. However, the precision was generally problematic for them. Because the material was very sensitive to external conditions and cutting parameters.

Robotic fabrication has recently become a very popular research topic in the field of architecture. Thus, it is possible to foresee that this technology will become more widespread in the future. Thanks to this course, we gained a good experience both about technical knowledge and the mutual connections between material performance – production technology – design approach. The robotic fabrication student project presented here is one of the starting points of such studies.

Students: Can Çobanoğlu, Hasan Talha Aksu, Muhammed Ölmez, Oğuzhan Akgün