Robotic Fabrication in Basic Design Studio

This paper investigates the integration of robotic fabrication into first-year undergraduate design education, particularly in a basic design studio. Traditionally, robotic technologies are not introduced at this level due to perceived skill gaps among novice students. The study demonstrates the potential and strategies for incorporating robotic arms into early design education through an experiment conducted at Istanbul Bilgi University. The experiment involved 32 students from various design disciplines, divided into control groups using hand-held tools and test groups using a Kuka KR-20 robotic arm.

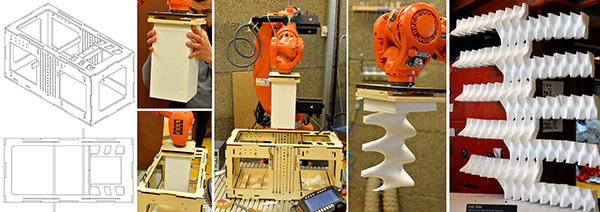

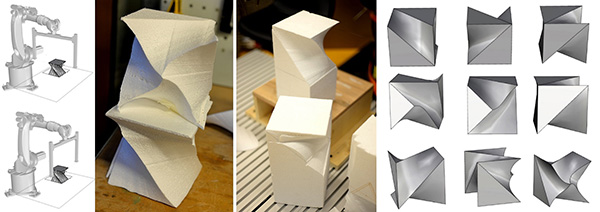

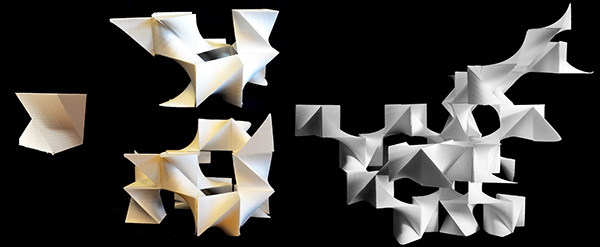

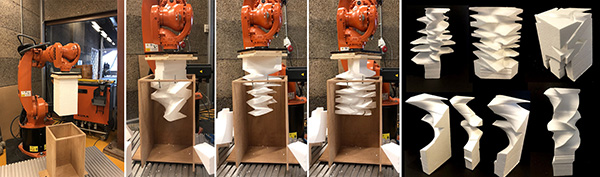

The studio experiments began with students using hand-held hot-wire cutters (HWC) to create solid and void compositions in EPS foam. This exercise introduced basic design concepts and techniques. The test groups then learned robotic arm operation and programming through tutorials and practical exercises. In the final assignment, all groups created systems of solid and void using HWC techniques. The results showed that while robotic fabrication presented challenges related to precision and control, it also enhanced students’ design skills. The R1 group focused on coding and precision, while the R2 group designed cutting mechanisms using the robot. Both groups adapted their hands-on processes to the robotic setup, revealing new design possibilities.

The study concludes that integrating robotic fabrication in first-year design studios is both feasible and beneficial. Students developed crucial design skills and confidence, learning to merge traditional and digital fabrication methods. Relevant factors affecting this integration include adequate time and resources for exploration and the interchange between traditional and robotic approaches.

You can find the original paper here.