Digital Fabrication Course: Day 1

In this semester, I started a new elective course at İstanbul Bilgi University Faculty of Architecture. Second, third and fourth-year architecture, interior design, and industrial design students attend the course titled “Digital Fabrication”. I am very excited to study the basics of robotic fabrication together with the students. I’ll try to report the content of the lectures and the robot exercises on designcoding.net. Below is the general brief of the course (not specific to any fabrication machine, however, this semester is about the six-axis robot.

This course will guide undergraduate students of architecture and interior design through digital fabrication technology. It is offered in several chapters which introduce students to necessary knowledge and hands-on experience of digital fabrication. After several lectures on mathematics, programming, and basic operational skills of computer-aided manufacturing (CAM) machinery, students are expected to propose a term project. The term project includes a wide range of topics, including; reducing waste materials and fabrication costs, issues on variation and similarity, precision and accuracy, geometry and materialization, tutorials and education, programming and add-ons. Students are expected to discuss, develop and present a unique approach to the use of new digital fabrication methods for a chosen design challenge. This is expected to widen their visions and help them define their own attitudes towards digital fabrication technologies.

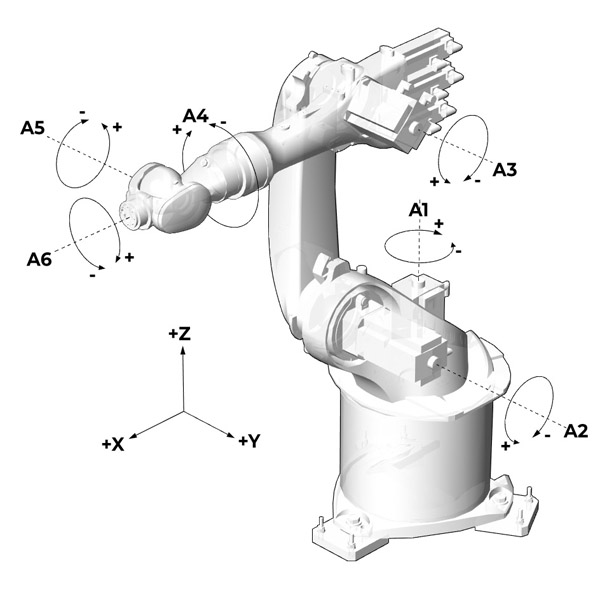

On day one; we had a short presentation about the robotic arm, its specifications, and safety rules.

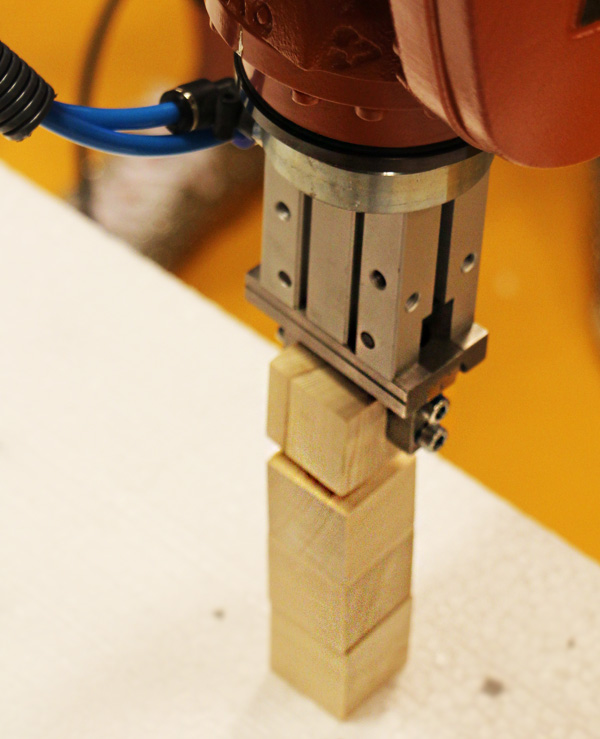

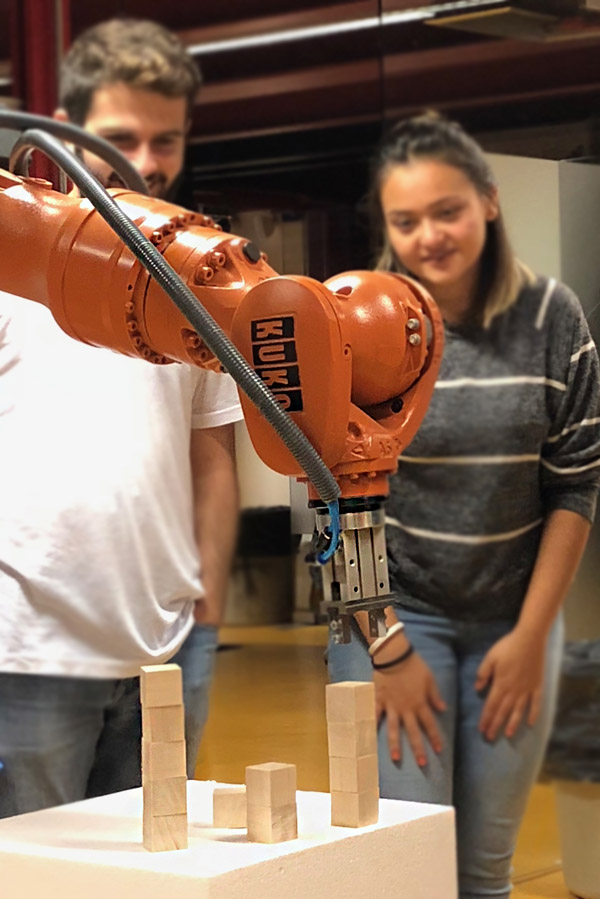

We also had a quick exercise. This exercise was intended to get familiar with the handling and usage of the smartPAD. We experimented with the jogging of all six axes, understanding positive and negative rotations. Then, tried cartesian jogging, understanding the X, Y, and Z axes of positioning the TCP, and A, B, C rotations around those axes. After getting comfortable with the above, we used a gripper tool to pick and place several wooden blocks on top of each other;

Photos: Meryem N. Yabanigül

Students were pretty excited to control the “monstrous-looking” machine on day 1.